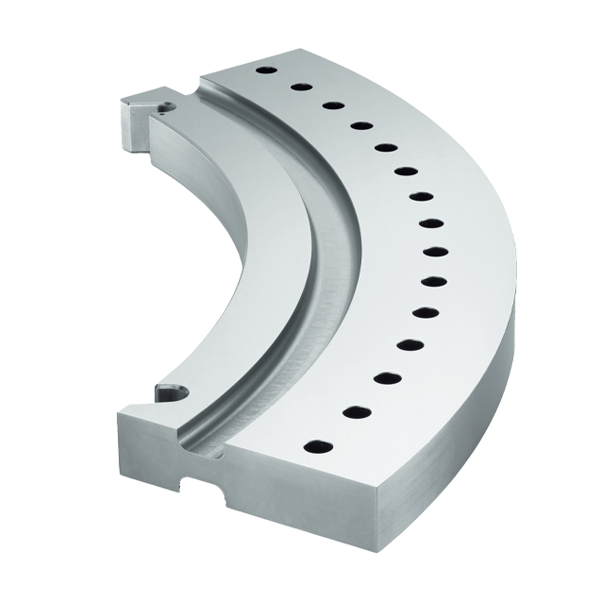

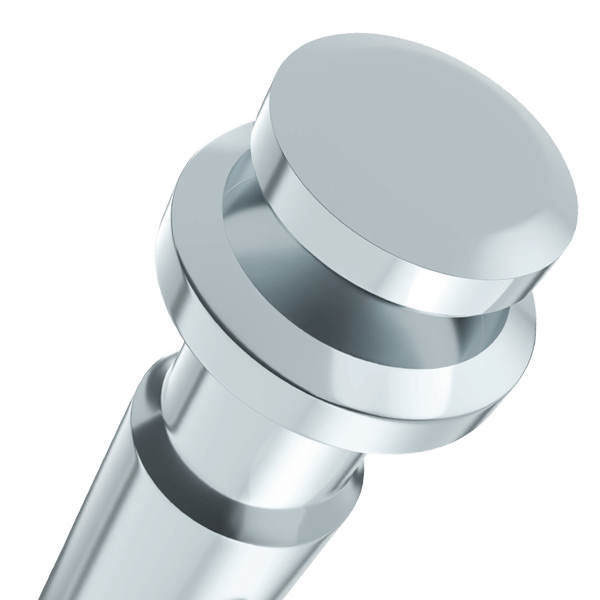

For 65 years, NOTTER Tableting Tools has been renowned for unique precision and top quality. Many years of expertise, combined with cutting-edge engineering and innovative production methods, enable us to manufacture tableting tools that far exceed the typical standard and are perfectly tailored to the respective application.